- Home

- EventsEvents

- Product Launches

- CategoriesCategories

- Advertise

- Opinion

HRS Group is globally recognized for providing a sustainable, energy-efficient range of heat exchangers and heat exchanger-based systems for the processed food industry. HRS has been at the forefront of thermal processing technology for the chemical process and food product processing industry. HRS has built its reputation in value-added engineering, manufacturing excellence and customer service.

In India since 2003, HRS Process Systems has been a wholly-owned subsidiary of the UK-based EIL-HRS group of companies, with a turnover close to Rupees two Billion.

Assuring the customers of high-quality products offered, V Gokul Das, chairman and managing director, HRS Process Systems, says, "Our factory in Pune is built to the latest standards and we are ISO 9001:2015 certified, which ensures a globally accepted quality system. Our facility is also ASME U stamp accredited, a key requirement for primary industry sectors like oil & gas, petrochemical, chemical, fertilizer, steel, power, etc., and exports to global markets."

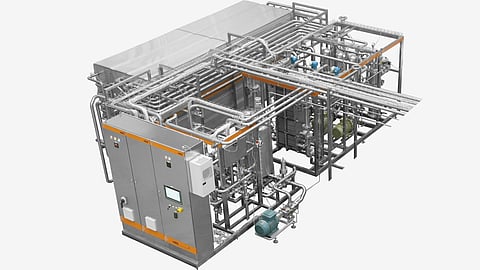

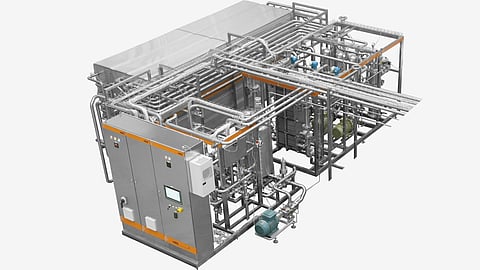

He speaks about HRS's products, "We manufacture a range of shell and tube heat exchangers, our flagship product Ecoflux corrugated tube heat exchanger, UNICUS scraped surface heat exchangers, plate type heat exchangers, evaporation systems for effluent treatment and other systems."

These products are incorporated in various industrial sectors such as pharma, edible oil, cement, paper, power, and most importantly, thermal treatment systems like pasteurizers, sterilizers, UHT(Ultra High-Temperature processing), and evaporators for the food processing segment.

HRS PSL works in various materials like Stainless steel (all grades), Copper-Nickel alloys, 904L, Alloy 20, Duplex, Inconel, Hastelloy, Titanium, and Tantalum.

Innovative heat transfer technology

According to Das, HRS is a well-known brand for innovative heat transfer technology and processing lines in the F&B segment. He says, "We successfully commissioned an integrated multi-fruit processing plant on a turnkey basis for a mega food park in Raipur, Chhattisgarh. These plants are designed to process fruits/ vegetables/ horticultural produce such as mango, papaya, guava, amla, tomato, chili, pumpkin, bottle gourd & bitter gourd, etc. The complete engineering, design and manufacture was done in-house. The raw materials are processed into purees, juices, and pastes with high shelf life and good quality."

R&D and Innovation at HRS

According to Das, the product texture, taste, or aroma can change due to improper processing and make the product unfit for consumption. Also, the food industry is developing many new products based on the market's demands. These need R&D effort and application engineering to conceptualize the process design and demonstrate key performance characteristics in a pilot version. HRS has a pilot thermal processing unit which can be taken to the customer location for conducting trials. The company provides energy-efficient designs, their key R&D effort in the thermal processing solutions business.

Das informs, "HRS has a group research center in Murcia, Spain. The technology developed is available for all the group companies to supply globally. Our patented product UNICUS Scraped Surface Heat Exchanger was developed in the center to cater to the thermal processing of viscous fluids and fluids with particulate."

Sharing information on the current work at HRS, he adds, "We are working on enhancing heat transfer efficiency for viscous and heat sensitive products by designing a special Rotary Scraped Surface Heat Exchanger (R-series). We also work on continuous cooking and processing lines for different ready-to-eat food products."

Trends in the F&B industry and the way forward

Das believes that the F&B industry has high growth and employment potential. A good policy framework to encompass agricultural produce, storage, transport, processing, and product in the consumer market will go a long way in enabling growth in this industry. He says, "Many companies have started backward integration and reaping benefits of an integrated approach."

Sharing his opinion on the food industry trends, he says, "The food industry is dependent on agricultural produce, which is seasonal and dependent on the vagrancy of nature, although contract farming and the use of hybrid varieties are picking up. The fruit pulp segment has had decent growth based on the "buy local" thrust in past years. The beverage segment is having a high growth based on increasing demand for fruit-based beverages and health drinks."

He comments on the processed food sector, "The processed food segment is beginning to take off, and a good innovative R&D effort will help this industry grow by leaps and bounds. We at HRS are looking at this segment to build on our expertise and provide solutions to our customers."

HRS at ANUTEC India

Speaking about their upcoming participation at ANUTEC, India’s largest international food and drink technology fair in September 2022, Das informs, “We will be showcasing our latest offering to the F&B industry at the exhibition. We will also share information about our recent installations and application details. We plan to display product samples and detailed information about how HRS technology/expertise is “top of the class” and beneficial to the food processing industry.”

Das believes that ANUTEC is one of the premium food technology business shows, with an international appeal with participation from domestic and international players. He adds, “ANUTEC provides the platform for all stakeholders- producers, processors, equipment suppliers, process technology experts, and customers, to interact and understand the latest development in their sector. The show enables business and product development.”

HRS looks forward to great interaction with the industry leaders and their teams at the upcoming event. He says, “We expect to generate good connections with our existing customers and build on new customers in the trade show. We also look forward to international exposure in this show whereby we can generate some good export business.”

Future plans

As per Das, HRS has the necessary products and process engineering expertise to build thermal processing lines that can convert raw agricultural/horticultural produce to desired liquid or concentrated form for use over a while. He says, “We are looking at building process lines that enhance productivity and give better quality products at lower prices. We are working on options for processing the waste generated in the industry into value-added material. Another area of our focus is process lines for various processed food and combinations, which has a growing market and can make a big difference in the food and nutrition program for the welfare of our countrymen.”

Regarding the company’s future plans, Das informs, “We look forward to building on the trust by providing solutions not only for the standard applications in heat transfer and food processing but also working on new challenges faced by our customers in bringing new products to the market. We believe this would help us grow in the coming years.”

Visit HRS at Stall no. B70 at ANUTEC India, BEC, Mumbai from 14 to 16 September to explore their innovative products.

To register for the event and make meaningful connections, click here!

Click HERE to subscribe to our FREE Weekly Newsletter