- Home

- EventsEvents

- Product Launches

- CategoriesCategories

- Advertise

- Opinion

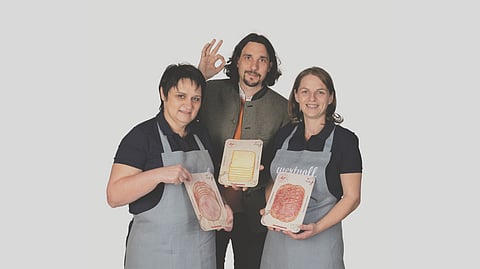

The Austrian, family-owned Kaufhaus Hubmann has been relying on packaging technology from SEALPAC to modernize its deli department. With the semi automatic SEALPAC M-Flex traysealer, and the resource-saving FlatMap and FlatSkin packaging solutions, this long-established company has found a solution to the challenges of the skilled labour shortage without compromising on quality, freshness, or customer experience. The M-Flex, which was successfully implemented at Kaufhaus Hubmann, can be experienced live at the SEALPAC stand at IFFA 2025.

Like many other food retail companies, Kaufhaus Hubmann, with locations in Stainz and Eibiswald in the south of Austria, faced a problem that affects the entire industry. Staffing the deli counter was becoming increasingly difficult due to a shortage of qualified personnel. The solution was a modern, semi-automated packaging system, which now allows them to offer freshly cut deli products of the highest quality several times a day, regardless of staffing levels.

Versatile in application

Kaufhaus Hubmann's new packaging operation has been achieved with the compact SEALPAC M-Flex traysealer, which, owing to its space-saving design, fast tool changes, and efficient rotation principle, is perfectly suited for smaller batches and frequent product changes. The M-Flex offers the full SEALPAC performance on a small footprint by handling a wide variety of modern packaging solutions. It processes all major packaging materials, including plastic, aluminium, and paper, with the highest degree of precision to create secure and attractive packaging. In addition to standard solutions, innovative concepts such as FlatMap, TraySkin, FlatSkin, or EasyLid can also be implemented. The M-Flex is fully electric, so requires no water or compressed air.

Highest efficiency and flexibility

With its innovative film transport and rotation principle, the SEALPAC M-Flex traysealer sets new standards in efficiency and precision, even when processing the thinnest films. Manual loading and unloading takes place ergonomically at the front, while the sealing process takes place simultaneously at the rear of the machine. The rotating table can be turned both left and right, making it suitable for any operator. Due to its continuous process, the M-Flex achieves outputs unattainable until now with semi-automatic systems. Safety features, such as an intelligent ID system that ensures that the M-Flex will only run if the correct tools are positioned in the machine, minimize operating errors. Its sophisticated tooling quick exchange system enables fast format changes on the M Flex for maximum flexibility in everyday production.

FlatMap and FlatSkin: sustainable and attractive

When selecting the right packaging solution, Kaufhaus Hubmann placed great emphasis on freshness, a high-quality customer experience, and the careful use of packaging materials. The choice fell on two modern solutions from SEALPAC that are ideal for meat products and offer an alternative to the traditional service counter:

• FlatMap: this solution, ideal for sliced products, provides a fresh look at retail with excellent branding opportunities and optional reclosability. By sealing under modified atmosphere, shelf life is extended. In the meantime, the sliced products are ready to serve from their packaging on the table.

• FlatSkin: this system, ideal for meat, poultry, fish, cheese, vegetarian products, and more, utilizes a deep vacuum, which increases shelf life. A highly transparent barrier skin film fixates the product directly onto its flat support, which allows for excellent vertical presentation.

Both solutions are based on flat cardboard carriers covered with an ultra-thin plastic liner. The individual components can be easily separated after use, allowing them to be disposed of in the appropriate recycling streams.

Excellent taste, maximum security

With the support of the M-Flex and SEALPAC’s modern packaging concepts FlatMap and FlatSkin, Kaufhaus Hubmann has found a solution that meets its high-quality standards and that delights its customers. The fine meat products in the deli department are now available freshly cut several times a day in the refrigerated section, optimally protected in packaging with a very low plastic content. The employees can once again concentrate on what they do best: providing advice and selling with passion. Florian Hubmann, managing director and owner at Kaufhaus Hubmann, is enthusiastic about the new solution: "We did not want to give up our deli department, despite staff shortages due to illness, retirement, or school obligations. For us, this is a solution that tastes good and provides safety, both for our company and for our region."

Experience the M-Flex live at IFFA 2025

Kaufhaus Hubmann’s success story demonstrates how even small-scale businesses can successfully enter into the world of professional packaging. The M-Flex offers them maximum efficiency in the smallest possible space and is so intuitive to use that even frequently changing staff can work with it. You are able to experience the M-Flex, and many other pioneering packaging solutions, live at the SEALPAC stand at IFFA 2025.

Meet SEALPAC at IFFA 2025 in Frankfurt am Main: hall 12.1, stand E79.

Click HERE to subscribe to our FREE Weekly Newsletter