- Home

- EventsEvents

- Product Launches

- CategoriesCategories

- Advertise

- Opinion

With an expected annual increase in production of about 5%, India is by far the fastest-growing market for butter production worldwide. And attraction is rising: While table butter is primarily associated with Western cuisines, its relevance to Indian eating habits is increasing. Traditional milk-fat products such as white butter and ghee enjoy unimpaired popularity. Butter processing plants in this region have to expand capacities significantly to meet the consumer's demand. To answer the manufacturers' need for highly flexible, robust, and economical technology, GEA is unveiling the GEA butter Maker 1000.

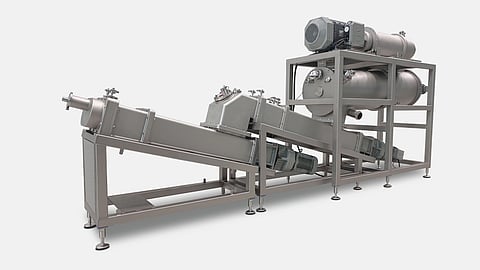

Robust, flexible, affordable – the butter Maker 1000 does it all

A result of an intense collaboration of GEA's international engineering teams, the new GEA butter Maker 1000 combines the best of the two worlds. It transfers the advanced design based on more than 80 years of experience in manufacturing premium quality table butter as per German butter standards to a new modular and robust design that also allows configuring the machine components for the production of white butter or butter for ghee processing.

The vast variety of feasible milk fat products is completed by dosing systems for brine or cultures.

Dimensioned for a production capacity of 800 – 1,800 kg of butter per hour, the design features robust drive systems and is controlled via a user-friendly HMI.

The machine features an open stainless steel frame design, granting quick access to all relevant parts, reducing planned downtimes for maintenance significantly and thus increasing the machine's productivity. Due to an optimized arrangement of the butter-churning cylinders and drive units, the footprint could be considerably reduced, making the machine especially attractive for replacement projects and lowering the installation efforts.

The churning process can be monitored via several illuminated sight glasses, while a camera and screen arrangement is available as an option for remote monitoring. During the churning process the butter granules are cooled via an internal buttermilk cooling system, eliminating the need for additional cooling water supply to the churning cylinder, making the butter cooling highly efficient. For producing premium table butter, the integrated vacuum system ensures an even structure and water distribution in the final butter.

"When developing the GEA butter Maker 1000, we aimed to provide a solution that tackles the challenges of Indian dairy customers looking for an economical, robust and flexible butter-making system for various milk fat products. Already now, we see other markets reaching out for this machine as well, which proves that we have answered widely felt pain points," says Christian Becker, responsible Product Manager for dairy applications at GEA.

Turnkey is not luxury – it's smart

For all dairies looking for a quick and hassle-free installation and startup, there is a complete skid including cream pre-heating, ingredient dosing, CIP supply and buttermilk collection and cooling available. Furthermore, GEA specialists master the entire value chain, from raw milk reception to the final butter, ensuring that the desired butter specification will be met. Because being up and running quickly for production is not a luxury, it's smart.

To know more and discuss your requirements, please visit GEA at IDF World Dairy Summit at India Expo Center from 12 to 15 September 2022. GEA is participating in the IDF exhibition and will be present in Hall no 3.

Click HERE to subscribe to our FREE Weekly Newsletter